Description

Specifications

| Product model | IPRM-G Starch Sugar Inline Brix Monitor |

| Measurement item | Brix,Refractive Index (nD), temperature. condiment, tomato Paste, Jam, chocolate, soy milk, cola, sugar, starch, sweeteners, ketchup, fruit juice, etc., |

| Measuring range | 0.00 – 30.00% Brix |

| Resolution | 0.01% Brix |

| Measurement accuracy | ± 0.1% Brix |

| Brix range | Temperature corrected 0-100°C |

| Process temperature | -10°C up to +100°C |

| Prism | Sapphire |

| Wetted parts | Stainless Steel SUS 316L |

| Power supply | 24 V DC |

| Interfaces | 1 output 4 – 20 mA,1 serial output RS485 |

| International Protection class | Display surface:IP65 Water resistant |

| Process pressure | Max. 1 MPa (145 psi, 10 bar) |

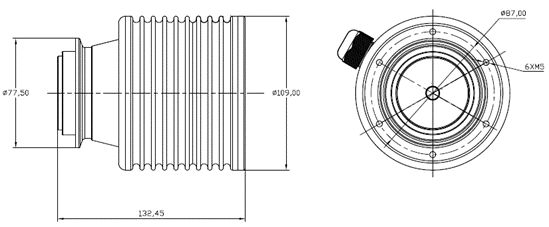

| Dimensions and weight | length 138 x diam.109mm; approx. 1870g |

| Cleaning components Options | IPRM-US, IPRM-Wiper

(No need to clean components for the food industry) |

| Fitting Options | IDF/ISO clamp union (1-3 inches), Flange, Compression Fitting G1/4 |

Dimensions

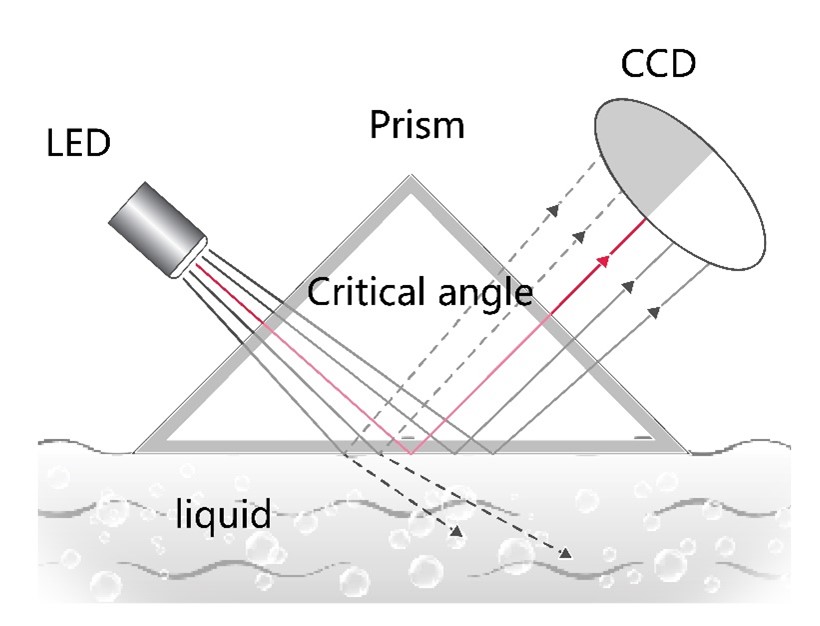

Measurement Principles

The refraction of light is a phenomenon wherein the direction that light is traveling changes as it passes through different mediums.

Through this phenomenon, we can observe as light’s direction changes and the “bent” appearance of substances even in the seemingly familiar, ordinary places in our day to day lives.

For example, imagine the lens of a pair of glasses and a pool.

When looking through the lens, an object appears larger or smaller than it is in reality.

When standing inside a pool, as you peer downward from the water’s surface, your legs will look shorter than they actually are.

As light moves from medium A (in this case, air) to medium B (lens and the pool’s water), it refracts.

Furthermore, it is known that light’s refraction changes depending on the concentration of a liquid.

The refractive index, which is a value that expresses the degree of refraction, is proportional to the density (mixture ratio) of a component.

Therefore, if there is 10g of sugar contained in 100ml of an aqueous solution and 20g of sugar contained in 100ml of an aqueous solution, the latter will have a higher refractive index value.

This difference in refractive index due to concentration variance has also been confirmed in solutions other than sucrose.

The properties of both the phenomenon known as the refraction of light and differing refractive index depending on concentration, are used as the principles of refractometers.

In addition to measuring the refractive index of a liquid, refractometers also display the concentration, converted from the refractive index.

Application highlights

IPRM-G Inline Brix Monitor It is a refractometer for in-line monitoring of Brix, It is an instrument with a wider measuring range, higher measuring accuracy and better temperature resistance, which can measure the Bailey’s Brix value of most solutions and slurries in the food industry.

The starch-sugar industry is one of the most important ways of industrialisation of agriculture and deep processing of food.

Food and beverage industry

Sugar, starch, sweeteners

Biofuels and fermentation industry